January 2026

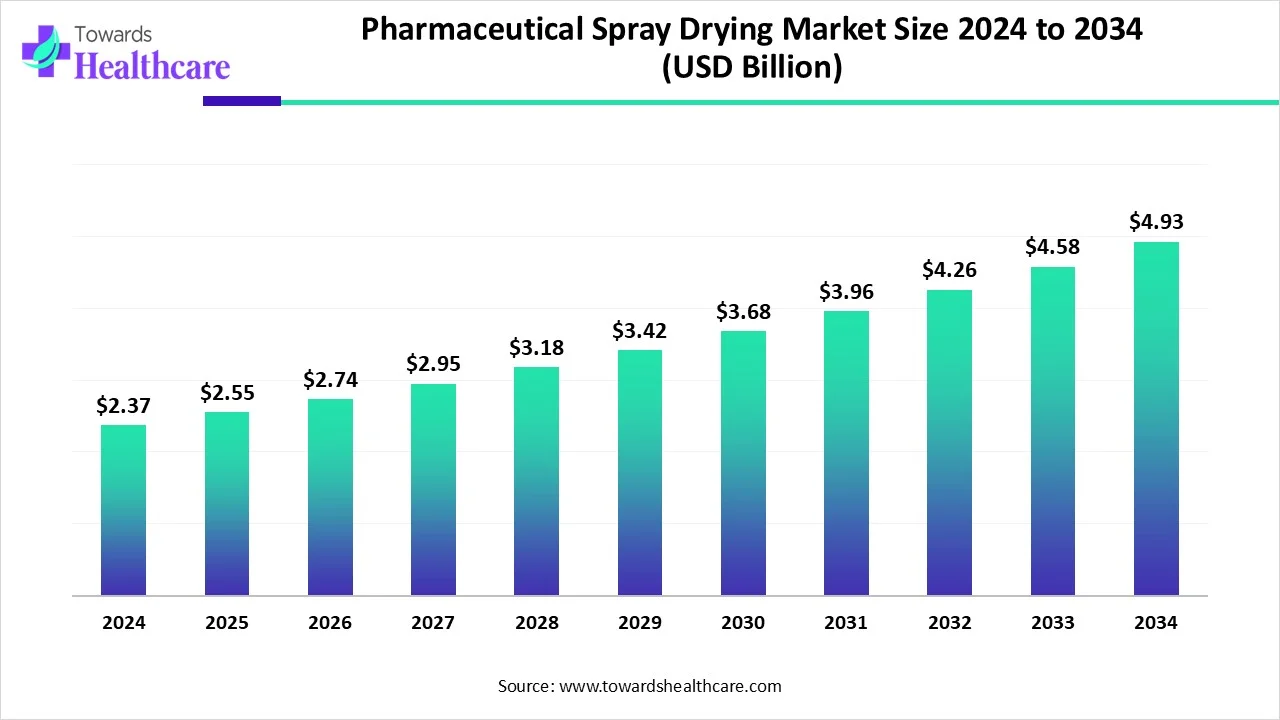

The global pharmaceutical spray drying market size is calculated at USD 2.37 in 2024, grew to USD 2.55 billion in 2025, and is projected to reach around USD 4.93 billion by 2034. The market is expanding at a CAGR of 7.67% between 2025 and 2034.

Currently widely used in the food and chemical sectors, spray drying is considered a rapid, cost-effective, and scalable process for the production of dry powder formulations of medicinal material. Due to characteristics like its reproducibility and continuous mode of operation, the method has become quite popular in the biotechnology and pharmaceutical sectors. There are prospects for market expansion due to the development of novel spray drying techniques, including controlled particle formation and supercritical fluid spray drying, that enhance product quality and delivery effectiveness. Microencapsulation, targeted drug delivery, and inhalation application advancements all contribute to market expansion.

| Metric | Details |

| Market Size in 2025 | USD 2.55 billion |

| Projected Market Size in 2034 | USD 4.93 billion |

| CAGR (2025 - 2034) | 7.67% |

| Leading Region | North America |

| Market Segmentation | By Application, By Type, By Technology, By Dosage Form, By End-Use, By Region |

| Top Key Players | Yamato Scientific America, Inc., NiTech Solutions LLC, Innovative Drying Solutions, LLC., Buchi Labortechnik AG, Novatech International, Inc., Anhydro, Inc., Armfield Ltd, B. Bohle Maschinen + Verfahren GmbH, JEL Drying Solutions A/S, Hosokawa Micron Ltd, Micron Powder Systems |

Various benefits are provided by spray drying pharmaceuticals to the manufacturers. It helps in developing stable molecular dispersions of drugs, as well as is a preferred option for BCS classes 2 and 4 drugs. At the same time, it also helps in controlling the density, particle size, and morphology of the drug delivery system. Furthermore, bioactive drugs are also effectively encapsulated with the use of spray drying. Thus, the use of spray drying is a preferred choice for heat-sensitive APIs and excipients. Moreover, this technology helps in enhancing the drug stability, delivery, and solubility.

With the help of AI, the working efficiency of pharmaceutical spray drying technology is enhanced. Moreover, new spray drying robots are also being developed, which improve an autosampler for automated sample collection, a computer-controlled feed mixing and pumping array, and a cyclone cleaner to minimize cross-contamination. Hence, this helps in the development of powder of different compositions, during a single run, reducing the time as well as manual effort. Thus, with the help of AI and spray-drying robots, researchers can explore the formulation design space more efficiently.

Why is Increasing Drug Developments a Driver in the Pharmaceutical Spray Drying Market?

To tackle the rising diseases, the development of drugs is increasing. At the same time, to enhance the absorption as well as bioavailability, the use of spray drying is increasing. Furthermore, the rising use of BCS class 2 and 4 drugs is encouraging the use of spray drying. Hence, with the help of spray drying, the products developed show enhanced efficiency. Moreover, inhalation products are also being developed with the use of spray-dried powders. Thus, all these factors drive the pharmaceutical spray drying market growth.

Limitations for Heat-Sensitive Drugs

In spray drying, the drugs are exposed to a hot drying chamber, which may not be suitable for heat-sensitive drugs. This may lead to unwanted effects, causing physical or chemical damage to these products. Thus, such products are degraded in the spray drying process, which results in the selection of alternative methods for heat-sensitive drugs.

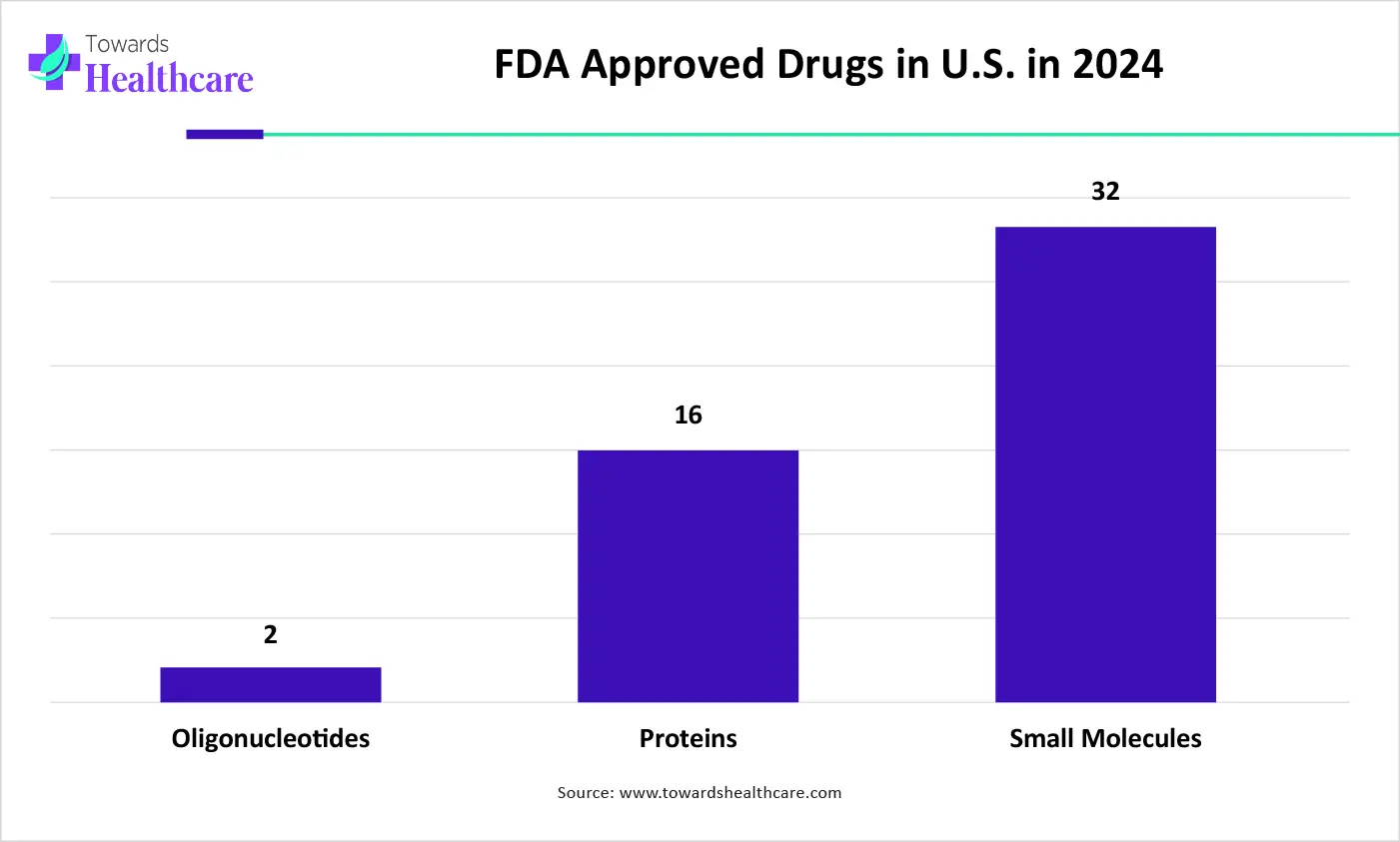

Growing Small-Molecule Research

The use of small molecules in the treatment of various diseases is increasing. This, in turn, increases the demand for pharmaceutical spray drying technology. The solubility of most of the small molecules is low due to which the use of spray drying is preferred. Hence, with the use of this technology, the solubility is enhanced, which in turn, increases the bioavailability. Therefore, the small molecules can be formulated in various dosage forms with improved particle size as well as stability. Thus, this promotes the pharmaceutical spray drying market growth.

For instance,

The graph represents the total number of drugs approved by the FDA in the U.S. in the year of 2024. It indicates that there is a rise in small-molecule drugs. Hence, it increases the demand for spray drying technology for enhancing their solubility and stability. Thus, this in turn will ultimately promote the market growth.

The pharmaceuticals segment, by application type, dominated the market in 2024. The use of spray drying in pharmaceutical development has increased due to growing innovation in drugs to improve their solubility, absorption, as well as bioavailability. This contributed to the market growth.

The fastest-growing segment by application type is expected to be the biologics segment during the forecast period. The development of biologics by spray drying is accelerating their production process, as well as new powdered formulations are also being developed, increasing their use.

In 2024, the market was dominated by the closed-loop systems segment by type. The closed-loop systems were a preferred choice for handling the flammable solvents in the drug production. Furthermore, it also provided process control.

The significantly growing segment by type is expected to be the open-loop systems segment during the forecast period. The use of open-loop systems is increasing due to the growing demand for powdered or granular formulations as well as water-soluble active pharmaceutical ingredients (API) or excipients.

The conventional spray drying segment, by technology type, held the dominating share in the market in 2024. The conventional spray drying technology was mostly used due to its reliability, as well as due to a wide range of formulation development, promoting the market growth.

By technology type, during the forecast period, the fastest growing segment is expected to be the enhanced spray drying segment. The use of enhanced spray drying is growing due to its use in the production of biologics as well as heat-sensitive drugs.

In 2024, the market was dominated by the powders segment by dosage form type. With the help of spray drying, the powder was developed, which in turn was used in tablet or capsule formulation, which were widely used. This, in turn, contributed to the market growth.

The fastest-growing segment by dosage form type is expected to be the granules segment during the forecast period. The production of granules for poorly soluble or absorbed drugs is increasing with the use of spray drying for the development of sustained-release formulations.

The small molecules segment, by end user, dominated the market in 2024. The use of spray drying technology for improving the bioavailability as well as the stability of small molecules was increased, which contributed to promoting the market growth.

By end user, during the forecast period, the significantly growing segment is expected to be the excipient segment. The solubility as well as stability of excipients are being enhanced with the use of spray drying, which in turn, increases their use in the development of new formulations.

North America dominated the pharmaceutical spray drying market in 2024. North America consisted of well-equipped industries along with the presence of skilled personnel, as well as technological advancements. Furthermore, the growing development of drugs enhanced the use of spray dying, contributing to the market growth.

The industries in the U.S. are increasing the use of spray drying technology to improve the solubility as well as the absorption of various active pharmaceutical products. Moreover, with the use of advanced technology, the product quality is improved with reduced errors and cost.

Canada consists of industries that are well developed, focusing on the development of new products with the use of spray drying. This, in turn, leads to new collaboration for the development of drugs with enhanced bioavailability by using the spray drying technique.

Asia Pacific is expected to host the fastest-growing pharmaceutical spray drying market during the forecast period. The Asia Pacific is experiencing a rise in the advancement of industries as they are adapting to various new technologies, as well as research, with the use of spray drying. This, in turn, enhances the market growth.

Along with the increasing use of spray drying, the industries in China are utilizing new technologies. With the help of these technologies, the working efficiency of spray drying is enhanced, improving the drug production, as well as the quality.

The industries in India use spray drying for formulating various drugs, as well as in research. Furthermore, new spray-dried formulations of poorly soluble or adsorbed drugs are also being developed.

Europe is expected to grow significantly in the pharmaceutical spray drying market during the forecast period. The industries as well as institutes in Europe are focused on the development of new drug formulations of APIs belonging to BCS Class 2 or 4. This increases the use as well as demand for spray drying, promoting the market growth.

The growing interest in the development of new drug products from poorly soluble or absorbed drugs, particularly from BCS Class 2 or 4, is driving the demand for the spray drying technique in Germany. Furthermore, new collaborations are also being formed.

The use of spray drying in the UK is increasing due to the growing research in industries as well as institutions for enhancing the bioavailability of drugs from BCS Class 2 or 4. These developments are further supported by the funding provided by the government.

By Application

By Type

By Technology

By Dosage Form

By End-Use

By Region

January 2026

November 2025

November 2025

November 2025