January 2026

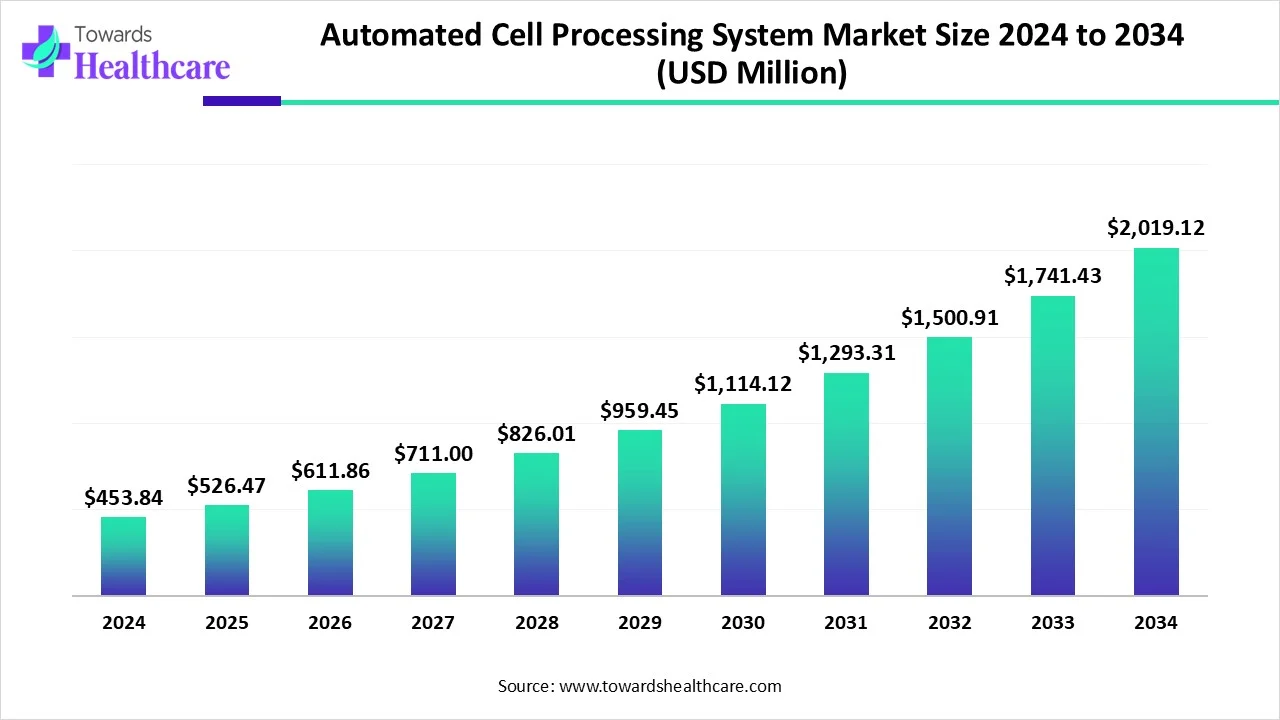

The global automated cell processing system market size is calculated at USD 526.64 million in 2025, grew to USD 611.11 million in 2026, and is projected to reach around USD 2331.24 million by 2035. The market is expanding at a CAGR of 16.04% between 2026 and 2035.

| Metric | Details |

| Market Size in 2026 | USD 611.11 Million |

| Projected Market Size in 2035 | USD 2331.24 Million |

| CAGR (2026 - 2035) | 16.04% |

| Leading Region | North America |

| Market Segmentation | By Steps, By Scale of Operations, By End Users, By Region |

| Top Key Players | Miltenyi Biotec, Lonza, Fresenius Kabi AG, Danaher Corporation, BioSpherix, LLC, Terumo Corporation, Sartorius AG, ThermoGenesis Holdings, Inc., CELLARES, Thermo Fisher Scientific Inc. |

The automated cell processing system market is growing rapidly as it provides advantages such as high-throughput analysis, lessens inter-operator variability, and offers critical data on cell concentration. These systems are instruments that mechanically carry out the steps contained in cultivating cells and maintaining a cell culture. These devices include bioprinters, automated bioreactors, and particular liquid handlers. Increasing the consistency and throughput of cell cultivation, automated cell culture systems are significant tools in cell line development, bioprocessing, and optimization of media and cultures. Automated cell culture systems regulate the temperature with heating, cooling, or both, while some allow constant monitoring of cells.

Integration of AI in the automated cell processing system is driving the growth of the market as AI-based bioprocess monitoring systems enable real-time adjustments to be made while production, ensuring that the therapy meets the mandatory quality standards. This integration of AI and automation is creating an extra-efficient, scalable, and precise manufacturing process. AI in analysing the data generated in the automated process and its abilities to further improve the efficiency and affordability of CAR-T cell production. AI-driven bioprocess monitoring systems allow for real-time adjustments to be made during production, confirming that the therapy meets the needed quality standards.

Increasing Automation in Biological Processing

Automation in cell therapy production lowers costs and minimizes errors and microbial contamination risks. It enhances scalability and quality. A comparative analysis of different automated systems underscores their appropriateness for cell therapy uses. Automation platforms can consolidate numerous processes into one. By automating manual tasks, many challenges in both upstream and downstream bioprocessing can be addressed, contributing to the expansion of the automated cell processing system market.

High Initial Cost Restraints the Market Growth

An automated cell processing system is expensive to buy, maintain, and use. The initial investment includes the price of the equipment, but ongoing expenses may come from consumables, maintenance, and reagents. This poses a significant barrier for smaller research labs, healthcare facilities, and startups with limited budgets, which restrains the growth of the automated cell processing system market.

Recent Advancements in Automated Cell Processing Systems

The upcoming generation of automated manufacturing systems featuring robotics is approaching. The Cell Shuttle (Cellares) and Multiply Labs’ robotic systems are designed to markedly enhance manufacturing throughput while significantly minimizing human intervention in cell therapy production. These systems operate in fully digital environments, where interconnected devices and machines work together seamlessly to optimize production, thus opening new opportunities in the automated cell processing system market.

By steps, the expansion segment dominated in the automated cell processing system market in 2024, as these steps increase in cell volume brought about by the increase in vacuolar volume and the concomitant rise in the surface area of cells. Cell expansion takes place over the entire cell surface. In which culturing isolated cells for multiple generations is required to reach the desired number of cells for a regenerative response in the patient. Cell expansion is the largest component of cell therapy development and manufacturing, as a single dose of cell therapy could need billions of healing cells.

The cryopreservation segment is expected to be the fastest growing in the automated cell processing system market because it aids in keeping biological material in a constant state at cryogenic temperature for any noteworthy amount of period, and helps to preserve the original cell structures. Cryopreservation is a well-established process for the long-term storage of cells and biological samples, reducing expenses and enabling the storage and transport of encapsulated cells from research laboratories to clinical facilities.

By scale of operation, the preclinical segment is dominant in the automated cell processing system market as these systems provide better efficiency, reduced human error, and enhanced reproducibility compared to manual methods. Preclinical automated cell processing systems provide numerous advantages, including increased efficiency, reduced human error, improved reproducibility, and affordability.

By scale of operation, the commercial organizations segment is expected to be the fastest growing due to its offer of industry-centred approach and cutting-edge facilities, allowing businesses to push the limitations of bioscience innovation. This organization supports research, creates, and manufactures a broad variety of commercial products, with most of them having healthcare applications. It operates differently from pharma companies, as they apply the procedures of living organisms to manufacture products.

By end use, the hospitals / medical centers/clinics segment is dominant in the automated cell processing system market, as delivery and manufacturing of these therapies are multifaceted, time-consuming, and expensive. Automated cell processing systems used in the hospital allow for on-site production, which eradicates the expenses associated with maintaining a separate facility and may increase access to cell-based products for a greater number of patients.

The commercial organization segment is expected to fastest growing in the market as these systems provide advanced efficacy, reduced human error, and improved reproducibility compared to physical methods. Cell therapy manufacturing to enhance reproducibility, efficiency, and quality while reducing labor and costs.

North America dominated the automated cell processing system market due to the presence of strong infrastructure in this region, as this research infrastructure offers the facilities, tools, and services researchers require to produce scientific knowledge. The growing use of cutting-edge technology in medical care systems and the increasing government funding are driving the growth of the automated cell processing system market. Novel and evolving technological and government frameworks are offering substantial opportunities for growth and innovation in the different medical care industries.

In the United States, personalized therapy is seeing increased interest as rising government investment, novel products entering significant clinical trials, and a surge in the number of diseases being targeted. Automation in cell therapy manufacturing reduces the expenses, challenges of errors, and microbial contamination risk. With progressions in manufacturing, inventors are becoming increasingly interested in commercializing automated bioscience processing, bringing them closer to becoming widely available to huge patients, which causes the growth of the market.

For Instance,

Canada makes revolutionary progress in the life sciences field, making ground-breaking contributions to personal and public health in this region. These innovations are growing with government support and Canada’s world-class R&D and innovative ecosystem. Canada’s life sciences sector has been a paragon of strength and economic vibrancy, making the country a global leader in healthcare innovation and drug discovery, acting as an engine of economic growth, and supporting the development, retention, and attraction of top scientists in a growing, high-value field, which contributes to the automated cell processing system market.

The Asia Pacific region is projected to experience the fastest growth in the automated cell processing system market during the forecast period, because rapidly increasing momentum in cell and gene therapy (CGT) studies in the Asia-Pacific region, driven by increasing patient demand and a thriving ecosystem of innovation. As the medical care sector is expanding in Asia-Pacific, the presence of large hospitals is often the main hub for innovation. Growing private funding and rising government grants in the region are supporting biotech companies to adapt to technical advancements, which drives the growth of the market.

China’s medical care business is experiencing rapid growth, driven by increasing incomes, growing health awareness, and an aging population. The healthcare industry presents a wide range of opportunities for industries and investors seeking to offer innovative and extensive quality services and products. Increasing health care outcomes in China is a top priority of the government. Rising investment and enhancing healthcare resources and capabilities, thus presenting a significant growth opportunity for the market.

Increasing technological advancements are playing a significant role in reshaping Indian healthcare, driving developments in treatment options, diagnostics, and patient care. The integration of telemedicine, AI, advanced diagnostic tools, and robotic surgery is transforming the healthcare sector. Major initiatives such as the Ayushman Bharat Digital Mission and private innovations in 5G are revolutionising healthcare and its access to the masses, which drives the growth of the market.

Europe is expected to grow significantly in the automated cell processing system market during the forecast period, as increasing patient awareness is driving demand for advanced therapies. Life science organizations in Europe receive the most public and private funding in the region. Recent advances in biotechnology have been facilitated by the development of novel analytical tools. It provides life science companies great stability, which contributes to the growth of the market.

Germany is a significant player in the global life sciences sector, boasting a strong ecosystem of biotechnology, pharmaceutical, and medical technology companies. Germany is a major hub for innovation, growing through strong public-private collaborations and cutting-edge research. The biotech industries in Germany are driven by a strong and stable healthcare market, support for research and development, and a wealth of companies and institutes. Germany provides the ideal investment environment for health innovation, which contributes to the growth of the market.

In March 2025, Andrew Jones, Market Development Manager with DeNovix, Inc., stated, “The launch of the CellDrop FLi further improves the reputation of the CellDrop range as the most advanced automated cell counter available.” (Source - Denovix)

By Steps

By Scale of Operations

By End Users

By Region

January 2026

January 2026

January 2026

January 2026