November 2025

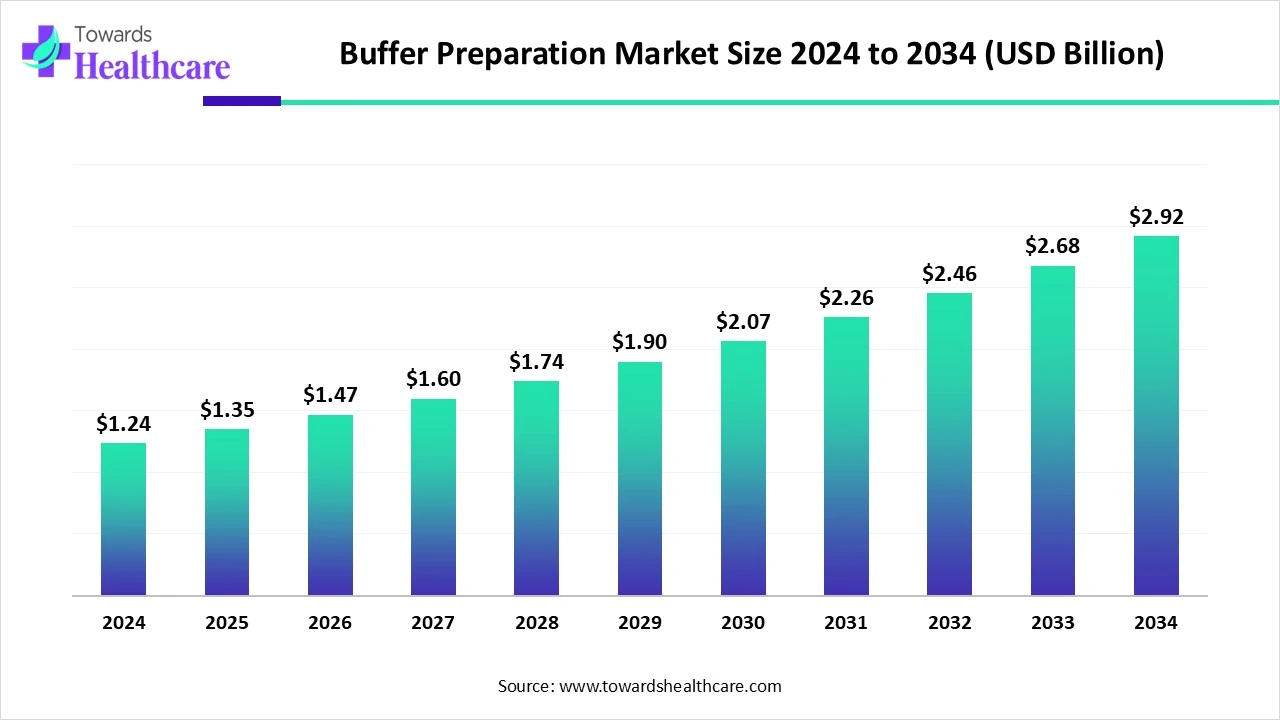

The global buffer preparation market size is calculated at USD 1.24 in 2024, grew to USD 1.35 billion in 2025, and is projected to reach around USD 2.92 billion by 2034. The market is expanding at a CAGR of 8.94% between 2025 and 2034.

| Metric | Details |

| Market Size in 2025 | USD 1.35 Billion |

| Projected Market Size in 2034 | USD 2.92 Billion |

| CAGR (2025 - 2034) | 8.94% |

| Leading Region | North America |

| Market Segmentation | By formulation, By Application, By Region |

| Top Key Players | Asahi Kasei, Avantor, Canvax, Cytiva, Lonza, Merck, Pall Corporation, Thermo Fisher Scientific, Uniogen |

A buffer solution is a solution that resists altering the pH of the solution on the small addition of acid or base. Nowadays, buffers are widely used in various upstream and downstream bioprocesses in different applications such as maintaining the pH environment, accelerating the output of the desired product, maintaining the purity, and stability of the end product during its operational features. The buffer preparation market is fueled by the increased prevalence of chronic diseases, with demand for new therapeutic solutions. Besides this, both academic and industrial sectors such as pharmaceutical, are emphasizing quality control in production and the R&D department.

AI can be applied in the preparation of buffer solutions according to the particular pH demand, estimating buffer stability, and also creating automated delivery systems for buffer solutions to several applications. In the preparation of buffer solutions for specific applications, AI algorithms can assist in analyzing a widespread database of buffer solutions and determine the suitable buffer solution system for respective use. Also, AI-integrated automated systems can support to delivery of the buffer solution and measurement of pH.

Increasing Demand for Automated Novel Buffer Preparation Systems

Currently, as the traditional buffer preparation system is lacking in several factors, like time-consuming, expensive, the raised automated systems can make it more convenient as they simplify the delivery system, raise the efficiency and accuracy of the buffer systems. With the aid of automation, sensors, novel buffer preparation systems are being developed with properties like pressure, temperature, conductivity, and pH sensors, which assure the precision in buffer preparation.

Convolutions of Buffer Solution Preparation and Rising Expenses

In biological production, numerous biochemical reactions are involved, which are mainly sensitive to pH, making buffer solution preparation a difficult and time-consuming process. This convolution is a rising challenge for new market leaders and can weaken the development of novel buffer solutions. In biopharmaceutical industries, buffers used are highly pure, which is obtained from the demand of pure raw materials and advanced techniques, which may raise the expenses in buffer solution preparation.

Increase the Service Provider of the Buffer Preparation

Currently, multiple pharmaceutical industries are nominating a subcontractor for the production of their buffer solutions to a specialized service provider. This increases the chances for providers to raise their services beyond just buffer production, inclusive of formulation development, fill or finish, and other services related to the production.

By formulation, the liquid buffers segment held the largest share in 2024. Liquid buffers possess major applications such as maintaining a stable pH, particularly in biological approaches, pharmaceutical formulations, and industrial methods. Liquid buffers are needed for enzyme activity, blood pH maintenance, and pH maintenance of solutions such as shampoo and contact lens solutions. Furthermore, these buffers are highly used in the R&D department of biopharmaceutical industries, including sample preparation, clinical trials, and drug development.

By formulation, the powder buffers segment is anticipated to grow at the fastest rate in the upcoming years. Various advantages of powder buffers are like, they possess longer shelf life as compared to other liquid buffers, accessible packaging (sachets or packets), and lucrative, etc. Usually, these types of buffers are widely used in, calibration of pH meters, including numerous industries like agriculture, cosmetics, and techniques like electrophoresis.

By application, the pharmaceutical and biotechnology companies segment dominated the market in 2024 and is estimated to grow at the fastest CAGR during the forecast period. Buffer solutions are highly employed in maintaining stable pH, upgrading the processes, and ensuring product quality and efficacy in pharmaceutical and biotechnology companies. In biotechnology, buffers play a vital role in protein purification techniques such as chromatography, in which they help to maintain the functional structure of the protein and prevent degradation. Other than this, buffers are highly used in biological sample handling, drug formulation, and are crucial for activity, stability, and solubility of the drug components and biological samples.

North America dominated the lab automation market in 2024 as buffers are significant in stable pH maintenance, and other conditions during biopharmaceutical manufacturing, like cell and gene therapies, biologics, and mRNA-based pharmaceuticals. Recently, the US has expanded its production capacity, especially for new drugs in the biopharmaceutical industry. In research laboratories, buffers are widely used in experiments involving nucleic acids, proteins, and other biomolecules.

In the global market, the US is a principal part of buffer preparation, which is fueled by the US’s supremacy in biopharmaceutical production. The market is facing growth, with rising anticipations specifying a vital increase in upcoming years, factors impacting AI-aided bioproduction, and increasing investments in novel biopharmaceutical facilities. Also, the US is witnessing the development of novel buffer technologies, including in-line buffer conditioning and continuous buffer exchange.

Canada is an extensive part of North America, and is seeing significant growth in the market as they are adopting the new technological advancements in novel buffer preparations, which can generate large volumes of buffers rapidly and efficiently, and is offering growth to the market. For biopharmaceutical development, like new therapies, biologics, cell and gene therapies, and mRNA-based pharmaceuticals are propelling the market growth.

Asia Pacific is predicted to be the fastest-growing region during the forecast period. Required stability, solubility, and efficacy maintenance for drug components during drug development and formulation are impacting the growth of the buffer solution market. Along with this, for optimizing and stabilize the vaccine integrity during the storage and administration period. Furthermore, buffers are widely applied in polymerase chain reaction (PCR) and electrophoresis, and are suitable for pH and ionic conditions for cell culture media in in vitro methods.

China is having robust growth in the market, specifically in the biopharmaceutical area, which is impelled by the rise in demand for buffers in numerous applications, like drug production, R&D, and bioprocesses. Also, an increase in demand for animal-free buffers, as animal-derived products are they are impacting the product quality.

In the widespread biopharma buffer market, India is experiencing crucial growth as there is a rise in the need for efficient buffer preparation systems. Significant applications are like pharmaceutical manufacturing, biochemical assays, and economical products like shampoos, lotions, in which pH matters.

The most important factors interfering are high needs for efficient, inexpensive buffer preparation methods, which are leading to the acceptance of new systems and outsourcing services. Buffers have a high significance in the maintenance of the stability and biological activity of products like antibodies, vaccines, and other therapeutic proteins.

The market is growing as there is a rising demand for buffers and challenges in conventional preparation methods. It is represented by a trend regarding the new buffer preparation systems and outsourcing to the intermediary service providers, proposing advantages such as cost effectiveness and rapid preparation frequencies.

The France market is widely impacted by buffers used in biopharmaceutical approaches, such as upstream (cell culture, media preparation) and downstream (purification, filtration). Besides this, the market is propelled by the increasing need for biological buffers and growth in biopharmaceutical production.

In February 2025, a global warehouse robotics supplier, Exotec®︎ has announced the commercial launch of the Next Generation of Skypod®︎ system with increased performance activity, upgraded storage density, and advanced software features. Romain Moulin, CEO and co-founder of Exotec, mentioned that the aim behind creating the next-generation Skypod is to generate the industry standard for operational superiority and smoothness for new generations. (Source - businesswire)

In December 2024, ZETA is an advanced and GMP-compliant technology, designed for the Buffer Inline Conditioning System (BICS), for improving buffer management, which provides the required production of high-quality buffers at the moment of use. This system has included multiple novel processing steps like mixing, monitoring, and regulating the buffer solutions concentration into a simplified and automated approach. (Source - Pharmaceutical Technology)

By formulation

By Application

By Region

November 2025

November 2025

November 2025

November 2025